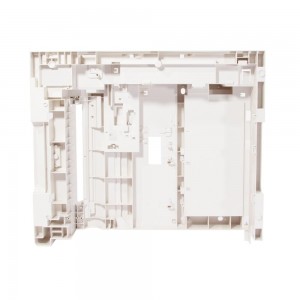

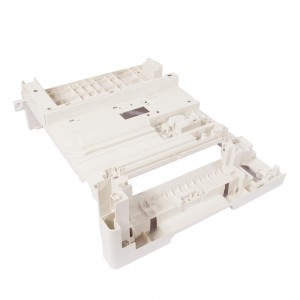

OEM designs custom printer housing injection molds

Specification

| Product name | Customized mould mold making plastic injection printer enclosure plastic part enclosure |

| Material | ABS, PP, Nylon, PC, POM, PU, TPU, TPV, PBT, PC+ABS, PE, PA6 |

| Weight | 2g-2kg |

| Drawing | Provide by customer(DXF/DWG/PRT/SAT/IGES/STEP etc),Or design according as the sample |

| Equipment | Injection molding machine |

| Surface treatment | Electroplate,paint spraying |

| Application | Auto parts,auto door handle,Car tank cap, housing/cover/case/base, telescope, daily goods, home&office appliances, other industrial spare parts, customized |

| Quality | 100% inspection before shipping |

| Packing | Carton packaging, or PVC bag with a label; Wooden pallet; as customer's requirement |

| Service | OEM service available, High Quality Competitive Price prompt delivery. 24-hour service with prompt reply |

Description

The case of the printer is made of universal plastic.General purpose plastics refer to plastics with large output, wide use, good affordability and low price.

There are five types of general purpose plastics: polyethylene, polypropylene, polyvinyl chloride, polystyrene and acrylic - butane - polystyrene co polymer. They're both thermoplastics.Shell printer can be compatible with different industries, unlimited materials, will not cause material damage, it meets the needs of the diversified market, can better provide users with more comprehensive production services.

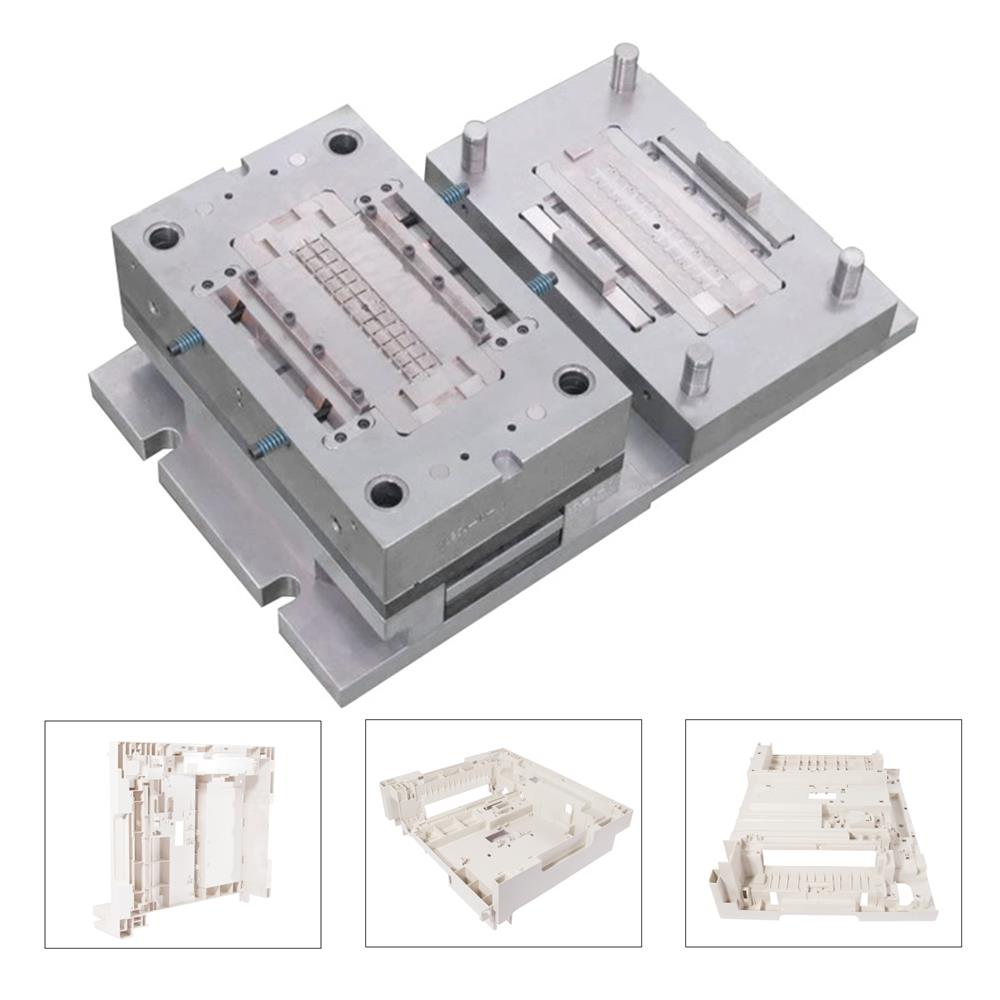

This design is for the printer shell injection mold design. The design adopts a mold a cavity, the gate adopts the dispensing mouth, the parting surface is selected in the largest section, the plastic parts are formed after the use of a push rod will be molded products from the moving die, the return use of the reset rod reset.The design needs to calculate the size of the plastic parts, determine the dimensional accuracy, and then the initial selection of the injection machine. As well as the injection molding machine pouring system, the structure of the forming parts, the size of the forming parts, the release mechanism, the exhaust system, the temperature control system were designed and calculated. And check the parameters of the injection machine, including mold closing thickness, mold installation size, mold opening stroke, mold locking force of the injection machine, etc. The injection machine model can only be determined after all parameters meet the requirements.