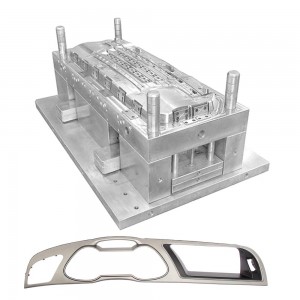

Auto parts injection mold

Description

1. Pouring system

It refers to the part of the flow channel before the plastic enters the cavity from the nozzle, including the main flow channel, the cold feed hole, the diverter, and the gate, among others.

2. Molding parts system:

It refers to the combination of various parts that constitute the shape of the product, including moving die, fixed die and cavity (concave die), core (punch die), molding rod, etc. The inner surface of the core is formed, and the outer surface shape of the cavity (concave die) is formed. After the die is closed, the core and cavity form a die cavity. Occasionally, according to process and manufacturing requirements, the core and die are made from a combination of working blocks, frequently from a single piece, and only in the easily damaged and difficult-to-work parts of the insert

3, the temperature control system.

In order to meet the injection process temperature requirements of the die, it is necessary to have a temperature control system to regulate the temperature of the die. For thermoplastic injection mold, the main design of the cooling system to cool the mold (can also be heated the mold). A common method of cooling molds is to set up a channel of cooling water in the mold and use the circulating cooling water to remove the heat from the mold. In addition to heating the mold, cooling water can be used to pass hot water or hot oil through, and electric heating elements can be installed inside and around the mold.